Why should you measure battery ground faults?

Battery ground faults are often times difficult to locate and create costly and catastrophic consequences if they remain undetected. The entire battery system will be compromised and subject itself to overheating, thermal runaway, and reduced battery capacity while creating a hazardous work environment.

Can the GFL3836 test AC Systems?

No, the GFL3836 Ground Fault Locator will only test DC systems.

How does the GFL3836 detect a fault?

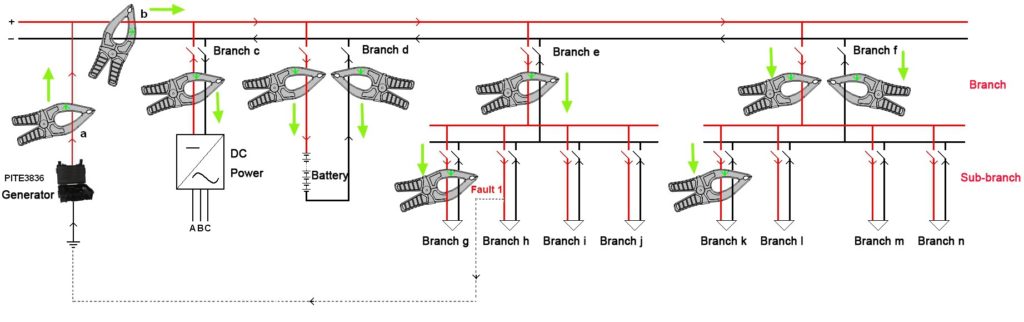

The ground fault detector works by injecting an AC signal into the bus system with respect to ground using the signal generator. The signal path is then traced using current clamps connected to the signal receiver. The direction of current flow is indicated on the receiver display, enabling the clamps to be moved to another branch or section of wiring. The measurement is repeated, the clamps moved again until the faulty part of the circuit is located.

What are some typical kinds of faults the GFL3836 can test for?

A typical supply to be tested will consist of a main bus connection with many branches to different loads or systems. Typical faults you may encounter are:

- Fault from the positive bus to ground.

- Fault from part of a load to ground.

- Fault between bus bars (partial short circuit).

- Fault from a branch to ground.

- Fault from bus to a separate circuit (‘Wire Mix’ connection).

- Leakage capacitance (This is not a fault, but leakage capacitance may be distributed around the system and will influence measurement).

In all cases, the actual impedance (resistance) of the fault may be very high, very low due to a short circuit, or anywhere in between.

How is the GFL3836 powered?

Both the signal generator and signal receiver use rechargeable batteries that can be charged using power supplies (110/220 VAC, 50/60 Hz) which are included in the GFL3836 package. The state of charge for each unit is indicated by the icon in the top right hand corner of the unit’s display. Both units may be charged while switched off. When the units are fully charged an indicator on the power supply changes from red to green.

How long do the rechargeable batteries last on a full charge?

The batteries will last for approximately 4 hours in normal use.